Articles

Current Inject Testing vs. the Cost of Conservatism

Industry standards are an invaluable resource providing guidance and historical precedent for engineering design. However, to apply to a broad array of locations and industries, the recommendations in these standards are often quite conservative.

The world of substation grounding standards is no exception.

In two recent Safearth projects, the utility customers were concerned with abnormally large costs of new substation ground grids. Both companies correctly applied principles in IEEE Guide 80 and used the two most popular grounding programs to design a “safe” grounding grid. These grid designs required dense grid spacing and a large amount of buried copper.

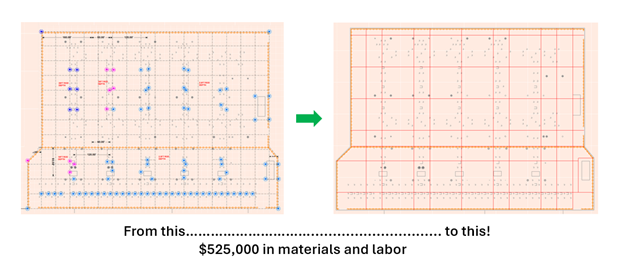

Upon review, our recommendation was to perform current injection testing. While these substations did not yet exist, transmission structures and other local substations did. Safearth performed current injection tests on existing transmission structures and substations to measure common grounding parameters (the ground potential rise, shield wire and neutral system impedances, touch voltages, transfer voltages) of existing structures. Measuring these parameters allowed Safearth to create accurate and optimal ground grid designs for the substations to be built in the midst of these structures.

The two Safearth designs met international safety standards with incredible cost savings. The first Safearth design eliminated 5500 ft of buried ground grid. The second Safearth design eliminated 6000 ft of ground grid and 15 ground wells. No amount of “safety” was removed. The testing allowed a more complete understanding of real conditions in the field – complicated soil conditions, unknown buried metallic infrastructure, distribution neutral system impedances, transmission shield wire impedances.

While the utility’s original designs were “safe,” and compliant to international safety standards, the original designs were also $500,000 apiece more expensive (and the cost of testing was a fraction of the cost savings).

No one would ever recommend reducing reasonable levels of safety to save money. However, having a better understanding of the engineering problems, risks, and hazards allows for the efficient application of funds. The money saved is now available for removing real hazards in the field, building needed infrastructure, or simply reducing the cost of the project!

The combination of the conservative nature of international standards, and the simplicity of computer estimations often lead the engineers to waste money to obtain levels of conservatism not justified by an increase in safety or reliability.

At Safearth, safety and cost are paramount to responsible engineering and design. Why estimate what you can measure? Let us help you today! If you have any questions, please reach out via email at grounding@safearth.com or call us at (877) 847-6863.