Articles

Technical Article – AS2067:2016 and the 1Ω Target

AS2067:2016 and the 1Ω Target

This article provides an analysis of traditional resistance target compliance at the distribution level and why it will need to be phased out with AS2067:2016

Earthing at distribution substations is the front line of protection for Australian power distributors. Fault currents and voltages are commonly transferred directly into houses, onto water taps, onto fences, into pools, all protected by the bastion of safety – 1Ω.

Introduction

“Under all reasonably foreseeable conditions the earthing system should not impose on any person or group of people an unreasonable risk” (AS2067:2016). This article demonstrates that it is reasonably foreseeable that designing distribution earthing systems to a local resistance (RG) limit of 1Ω for common earthing can present a non-negligible safety risk to the normally behaved and exposed individual. If the designer is submitting designs under such a pretence and not actually assessing the risk of fatality, then as the duty holder, it may be true that they are in contravention of AS2067:2016 and acting with negligence.

AS2067 Changes

AS2067 has recently undergone a major revision from the previous 2008 version. A significant change between the revisions, reflecting current trends in the industry over that period, is a shift in the earthing system management paradigm from safety targets to risk management. AS2067:2008 states its position clearly as: “The earthing system, in combination with appropriate measures, shall maintain step, touch and transferred voltages within the voltage limits” (AS2067:2008).

This is in contrast to the position which has been adopted in AS2067:2016, which has as its key principles in relation to earthing, risk management and due diligence. The risk in terms of the safety of people should be ‘negligible’ or ‘tolerable’. If the risk is classed as ‘tolerable’ then it shall be acceptable as long as all reasonable measures are taken to reduce the risk.

You can see the clear difference between AS2067:2008 and AS2067:2016 being that the former has distinct pass/fail, safe/deadly, voltage limits whereas the new revision has a risk management approach. Indeed where the archetypal 1Ω method fits within either approach is anyone’s guess but, it’s thought AS3000 is responsible.

The 1Ω Example

Consider the common scenario of a ground-mounted or padmount kiosk substation to be installed at a new residential subdivision. Let us assume the earth fault level is provided by the utility at just over 3kA due to an upstream reactive source and line impedance of 2.3Ω on the 11kV system. We will assume the protection clears the fault in 0.5 seconds. We have designed the HV and LV earthing systems to achieve the target earthing system resistance of 1Ω each and so the HV and LV earthing systems at the substation are combined as many standards will sanction. The design meets the 1Ω RG target and it would be approved and installed. Sounds too good to be true – and yes, it is!

Note that a 1Ω LV system is quite typical. For example, give some thought to the builders of the first houses in the development, working prior to the distributed LV neutral being of sufficiently low resistance to bring about a safer environment.

The Risk of this Design

If we calculate the risk posed by this design, we will find that it is unacceptable. Tools exist to quantify, and to demonstrate the risk an earthing system presents, however few distribution earthing designers presently use them. AS2067:2016 requires designers to be cognisant of risk based methods.

Let us first recalculate the fault current for a HV earth fault, taking into account the resistance of the buried earthing system at the substation and allows the fault level to be recalculated as follows – ,noting the source is assumed as purely reactive. and the MEN is yet to be developed:

IF = (1.1pu × 6.35kV) / (2.33ΩREACTIVE + (1ΩHV || 1ΩLV)) ≈ 3kA.

The EPR at the common substation is:

EPR = 3kA × (1ΩHV || 1ΩLV) = 1.5kV

By using software, or empirical formulae, to model the response of the soil around the substation due to the fault current, the touch voltage magnitude in this case can be determined to be approximately 30% of the EPR, so:

1m Touch Voltage = 30% × 1.5kV = 450V

In this instance the applicable resource for safety criteria is AS7000 which is consistent with the new AS2067. The applicable safety curve from these standards is the TDMEN contact scenario which implies the exposed individual is in contact with an MEN referenced item such as a tap that has risen in volts relative to the soil adjacent. The touch voltage level representing negligible risk based on the TDMEN curve is 272 Volts.

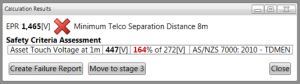

Hence the safety risk assessment identifies the hazard as non-negligible risk and the hazard is deemed non-compliant, as shown in Fig 1. Reasonably practicable measures must now be taken to reduce the risk.

The real problem with this design approach is that the key player has either been ignored or is non-existent – the MEN network! It is the low resistance of the MEN that delivers safety; if the MEN does not exhibit low resistance and other important characteristics then adequate safety cannot be guaranteed.

AS2067:2016 Risk vs Resistance Targets

It is clear in the example above that the distribution substation’s local earth resistance has little to do with the actual risk posed by an earth fault on that installation. Ultimately, earth fault related voltages must be assessed and controlled to reasonable levels to exercise our duty of care.

Many service providers submit reticulation designs to power utilities and believe that by following the standard designs or by meeting stipulated resistance targets such as 1Ω that they are protected in the event of the unspeakable. But this is simply not true and as the designer of the earthing system it is incumbent upon the designer and the utility to manage the risk appropriately: “If hazards cannot be reduced (reasonably practicably) to negligible levels, an assessment of risk is required” (AS2067:2016). Risk levels are rarely calculated when an RG target has been met and the utility and designer will be in breach of AS2067 by not performing this assessment. Even worse is the scenario where the risk level can easily be shown to be non-negligible and nothing has been done to ensure risk mitigation is performed to levels as low as is reasonably practicable (ALARP).

Solution

With the release of AS2067:2016 comes the requirement to assess if the earthing system imposes an unreasonable risk on any person or group of people. This assessment requires the designer to be more aware of the key requirements of an earthing design. Methods of accurately calculating the resistance of the MEN will become crucial and the earthing design process must be understood and documented. It is becoming clearer that specialist training and software will need to be made available and a greater level of understanding and awareness of earthing systems across the industry is desperately needed.

Summary

If you are presently designing to a target RG for distribution earthing systems, then the design may result in a quantifiable and unacceptable risk to personal safety. Ignoring the risk could then place you at risk of facing the coroner in the event of a fatality. Safearth provide assistance in these areas by supporting designers with training and software tools to enable earthing designs within the new risk framework of AS2067. Remember, ignorance is not a legal defence in the eyes of the court.